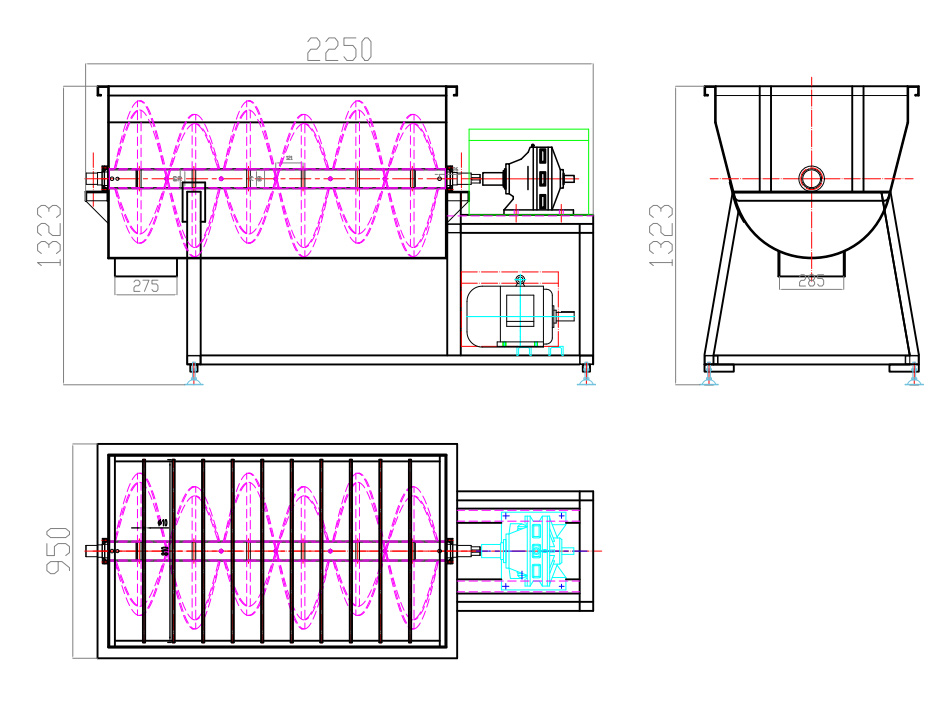

LG-700 Powder Mixing Machine

Ⅰ、Equipment introduction

Lg-700 powder mixing machine (mixer) is a new type of high efficiency mixing equipment, the mixer is horizontal positive and negative spiral forced force, the two inner and outer ring from the left and right sides in the opposite direction to promote the material axial displacement, so that the material convection, shear and diffusion between each other, in order to achieve the purpose of uniform mixing. If material accumulation is found, the motor will be reversed.

This machine is widely used for mixing various elements in vegetable processing, seasoning, food, chemical industry, medicine, salt, feed and other industries. It has the characteristics of fast mixing speed, high mixing uniformity, high efficiency, good mixing quality, short unloading time and less residue. Suitable for dishes, thick, paste, powder mixture. According to customer requirements can be equipped with automatic discharge device and simple valve port packaging facilities, in order to facilitate customer operation, fast.

Dehydrated vegetable industry is used for blanching, cutting, dewatering and drying vegetables before stirring glucose, maltose, lactose and other auxiliary materials.

Ⅱ、Main parameters of equipment

|

Item |

Unit |

Parameter |

Remarks |

| The barrel volume |

L |

780 | |

| power |

Kw |

5.5 | |

| voltage |

V |

380 | Can be customized |

| frequency |

Hz |

50 | |

| Mixing efficiency |

% |

95-99 | |

| capacity |

Kg/h |

2000-4000 | |

| Effective size of mixing drum |

mm |

1500×850×760 | |

| Inlet height |

mm |

1330 | |

| Inlet dimension |

mm |

1500×850 | |

| Outlet height |

mm |

445 | |

| Discharge port size |

mm |

275×200(Can be customized electric, air butterfly valve) | Can be customized |

| Overall dimensions |

mm |

2230×950×1130 | |

| weight |

Kg |

370 |

(Equipment assembly outline drawing)

Ⅲ、Equipment installation

1. The machine must be placed on a solid dry, ventilated level ground, and the ground must be calibrated with a level instrument to ensure that the machine works smoothly and reliably.

2. The voltage used by the machine is 380V, and the power supply voltage is determined to be consistent with the voltage used by the machine; Power switch should be installed outside the body before entering the line.

3. The grounding wire is reliably grounded, and the power line is fastened and sealed with the inlet and outlet parts of the machine to avoid water leakage and electricity leakage.

4. There should be no impact vibration or abnormal sound when the machine is running empty. Otherwise, the machine will be stopped for inspection.

Ⅳ、Steps of operation

1. The operator should be familiar with the performance of the whole equipment and understand the function and operation method of each component of the unit.

2. before starting the machine, we must carefully check the connection parts of mechanical and electrical equipment, bolts and other should not be loose, whether there is a stuck phenomenon, do not fall into foreign bodies, all normal before starting.

3. the machine can feed after normal operation, the main material and premix into the body at the same time, evenly feed, not a large amount of sudden pouring, material surface to the main shaft above, start timing, positive turn 1 minute reverse 1 minute, and then positive turn 1 minute reverse 1 minute, 4-6 minutes after the start of unloading.

Ⅴ、Matters needing attention

1. according to different kinds of materials, should be added less frequently, mixing time determines the uniformity, material shall not be mixed with sundry hard objects, wire, otherwise affect the life of the machine.

2. before the production starts, first no-load operation test, check the operation of the mixing shaft, check whether the transmission part is normal.

3. do not place any irrelevant items on the machine, so as not to start the accident.

4. Once abnormal phenomenon is found during operation, the power supply should be cut off immediately (emergency stop button) and stop for inspection.